Why Metal Fabrication Professionals Excels at High-Volume, Repeat Production Runs

At Metal Fabrication Professionals, we pride ourselves on our ability to excel at handling larger production runs and repeat work. This capability is mainly due to the advanced automation and equipment we have invested in over the years.

Continue reading to discover how our precision metal fabrication services are a perfect fit for high-volume, repeat production.

Why MFP Is Suited for High-Volume Production

We’ve invested heavily in cutting-edge equipment to support the high-volume production of components. Let’s explore some examples:

Lights-Out Production with Our Automation Cell

One of the critical pieces of equipment that sets us up for high-volume production is the automation cell we’ve added to our laser cutter. This system is designed to load and unload material efficiently and automatically, allowing us to operate lights out. Here’s why this capability is particularly beneficial for higher volume production runs, as well as repeat work:

- Shorter lead times: Our production process becomes significantly faster with automated material handling. As a result, our team can deliver parts to our customers more quickly.

- Reduced labor costs: Operating unmanned and lights-out minimizes the need for manual labor. This efficiency translates into cost savings, which we pass on to our customers.

- Consistency and precision: Automation ensures that each piece is produced with the same high level of accuracy and consistency – making it a perfect fit for higher volumes of repeated work.

Robotic Welding Capabilities for High Volumes

Another major asset we have on the shop floor is our robotic welder. This equipment is ideal for high-production runs, allowing us to handle larger quantities more productively.

Our robotic welding capabilities are most effective in larger volume projects where the investment in necessary fixtures is fully justified. While creating the fixtures for robotic welders can be a significant upfront expense, this cost is distributed across larger production runs. This makes robotic welding a highly cost-effective solution for high-volume projects, ensuring optimal efficiency.

Why MFP Is Equipped for Repeat Work

At MFP, our equipment and processes are designed to accommodate repeat work seamlessly. Here are some of the key features that enable us to excel in this area:

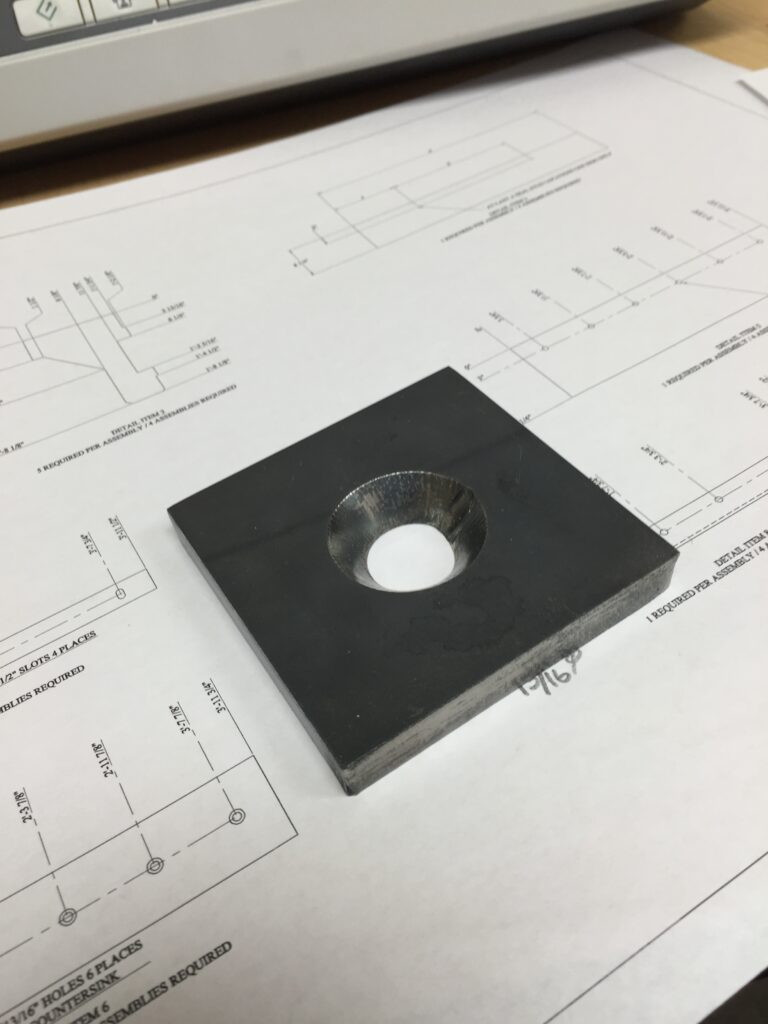

Our CNC Press Brake

Once programmed for a specific part, our CNC press brake can consistently produce thousands of parts with minimal manual intervention, making it a critical piece of equipment for high-volume, repeatable work.

Large Quantities of Material On-Hand

Our setup allows us to keep material on hand for clients with repeat orders, ensuring we start production without delays. We also have access to a large steel inventory, further aiding our ability to handle repeat work efficiently.

Versatility in Production

While we excel in high-volume production, we also have the flexibility to take on smaller, more custom orders. Our team can do it all:

- Custom, small batches: Our skilled team and advanced equipment can handle intricate, custom orders with precision.

- High-volume production: Our automated processes and high-capacity machines ensure efficiency and consistency for repeatable work.

Metal Fabrication Professionals is an ideal partner for customers seeking large production runs and repeat work. Whether you need custom parts in small batches or high volumes, MFP has the equipment, expertise, and dedication to deliver exceptional results.

Request a quote from MFP to get started.