At Metal Fabrication Professionals, quality isn’t just a one-off step toward the end of our process — it’s a guiding principle woven into every facet of our operations. From the moment raw materials arrive to the final inspection, our rigorous quality control processes ensure that each part meets the highest standards.

Let’s delve into the critical aspects of our quality control framework and understand why they matter to the MFP team and OEMs that partner with us.

Material Inspection

When materials arrive at our facility, the MFP team gets to work, meticulously scrutinizing every sheet. We check for imperfections such as scratches, rust, or gouges that could compromise the integrity of the final product. Our highly skilled personnel conduct visual inspections, paying attention to easily overlooked details such as mill stamps and surfaces vulnerable to damage caused by material handling.

We go the extra mile to ensure protective coatings, such as onion paper and vinyl-coated components, remain intact. Additionally, our team utilizes a “white glove treatment” for high-polish jobs requiring special handling.

The Metal Fabrication Professionals team sets high standards from the outset so we can mitigate the risk of defects and ensure all materials are prepped for production.

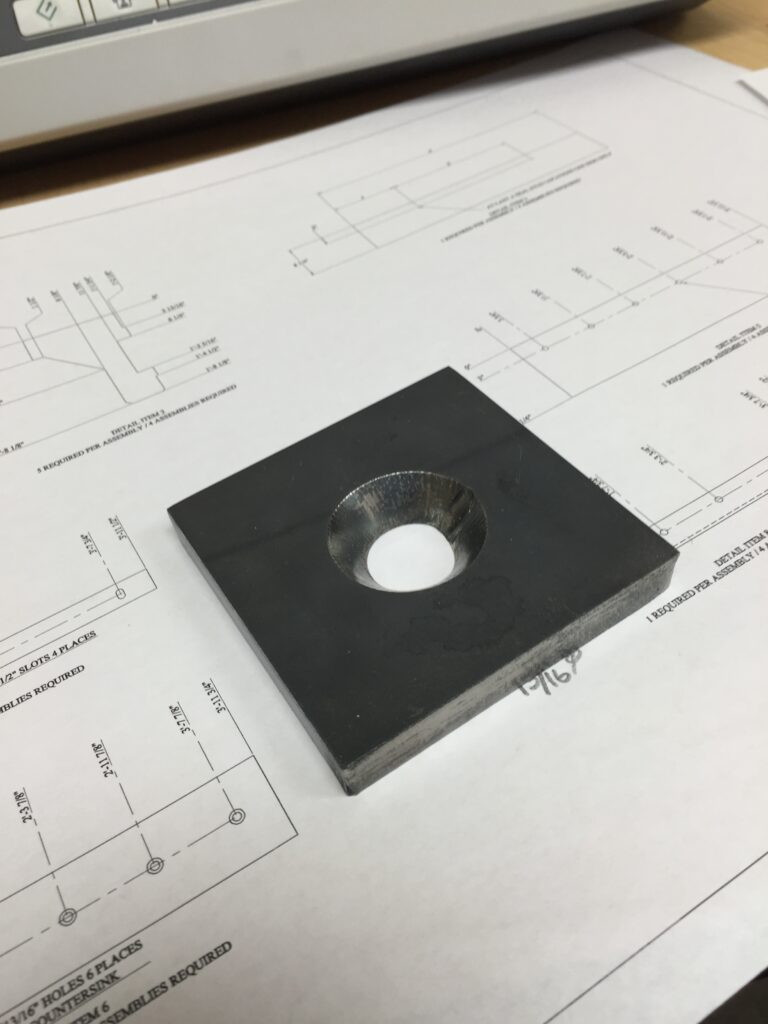

Dimensional Accuracy

Dimensional checks guarantee precision in our output. Whether it’s basic measurements using tape measures or intricate tolerances requiring calipers and micrometers, we leave no room for error. Our operators are equipped to detect deviations from programmed specifications, promptly addressing anomalies to maintain integrity throughout our machining services. This proactive approach enhances efficiency and minimizes rework.

Visual Inspection from Operators

Our operators are on the frontline throughout production, ensuring quality during machining and fabrication. Conducting visual checks at each stage, they scrutinize the integrity of parts, flagging any deviations from standards and specifications.

Quality Control by Welders

Like our operators, MFP’s welders inspect parts during the process. However, this group adheres to extra stringent protocols that include meticulous documentation of their work and ensuring welds meet precise specifications. Documentation of our welding services tracks the following:

- Who handled welding

- What time the welder completed their work

- What time inspection occurred

- The weld size and width

- The part’s dimensional requirements and its adherence to the specified tolerance

- The presence of porosities, undercutting, or cold-lapping

This hands-on approach fosters a culture of excellence where every team member is invested in delivering superior results.

Final Quality Control

Before any product leaves our facilities, our dedicated QC department undergoes a comprehensive final inspection. Every aspect, from surface finish to welding integrity, is scrutinized against stringent criteria. If the piece meets all requirements, it will be prepared for shipping. If our QC team identifies any discrepancies, the part is reworked or rejected. If the latter occurs, the process starts over again, beginning with material selection and inspection.

Exceeding Customer Expectations through High-Quality Machining Services

At Metal Fabrication Professionals, quality assurance isn’t just about meeting customer expectations – it’s about surpassing them. Our personalized approach to quality control ensures that every part we produce is defect-free and crafted with precision. By investing in rigorous processes and fostering a culture of excellence, we deliver value that goes far beyond compliance. Our customers can trust that when they request a quote from MFP, they’re not just getting what they asked for – they’re getting a superior product backed by a commitment to quality.