Crafting a Legacy: MFP’s Role in Bringing Renowned Artist’s Vision to O’Hare Terminal

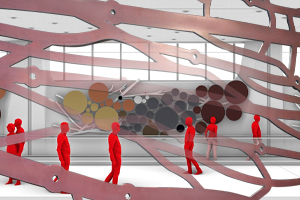

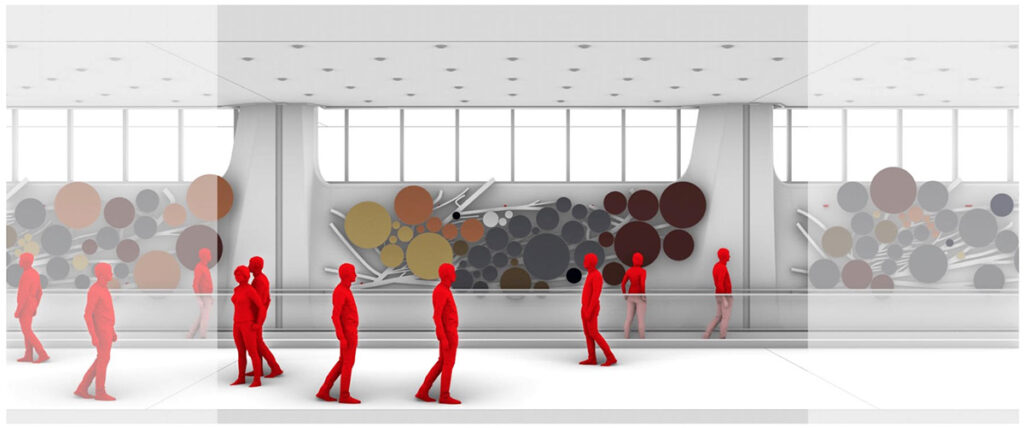

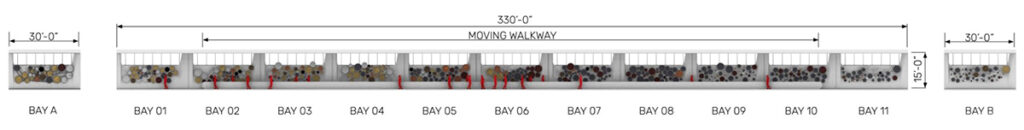

One of the latest works in MFP’s ongoing journey of pushing the boundaries of metal fabrication is coming to life in a terminal at Chicago O’Hare airport. Our mission to bring artistry and innovation to life takes an exciting turn as we embarked on a project of unparalleled scale and significance. Last summer, MFP was awarded the prestigious opportunity to contribute to the creation of a 360-foot piece of artwork alongside the mobile pedway at Chicago O’Hare’s Terminal 5. This artwork, designed by the talented Jina Valentine, is a visual celebration of Chicago’s demographic growth over the years, represented by a stunning array of anodized aluminum discs.

Visionary Artist, Metal Shop Craftsmen & Large Scale Venue

Jina Valentine is an artist renowned for her unique approach to storytelling through art. Her vision for this project is nothing short of exceptional. The artwork aims to capture the demographic evolution of Chicago, a city steeped in history and cultural diversity. The heart of Jina Valentine’s concept lies in the meticulous arrangement of anodized aluminum discs, each varying in size set atop of the aerial roadmap map view. These discs represent the city’s demographic growth over the years, a testament to the vibrant history and continual evolution of Chicago. To do justice to Jina’s concept, a perfect marriage of creativity and precise metal fabrication was required.

MFP’s Contribution: Crafting the 1/2″ Mild Steel Back Drop

Our role in this grand artistic venture involved the metal laser cutting of sixty 96”x120” sheets of 1/2″ mild steel. The complexity of the artwork presented us with a multitude of challenges, but our team’s unwavering dedication and expertise prevailed.

The Craftsmanship Behind the Scenes

The process of crafting this artwork has involved unparalleled attention to detail. It required a deep understanding of materials, fabrication capabilities and the artistic intent behind every piece. The fabrication team worked tirelessly to ensure that our metal work blends seamlessly with Jina’s vision, and we couldn’t be prouder of the results.

A Project of Remarkable Scale

This project is nothing short of monumental. It celebrates the history, culture, and diversity of Chicago while showcasing the heights of artistic vision and metal fabrication expertise. We are honored to be a part of this venture and thrilled to see it unfold.

The Road Ahead

As we move closer to the completion of the artwork installation at O’Hare Terminal 5, we look forward to sharing the final project with the world. We appreciate the dedication and commitment of the entire MFP team in making this project a reality. Stay tuned for updates on the project’s progress.

MFP’s involvement in this project is a testament to our unwavering commitment to creativity, craftsmanship, and innovation. We believe that this artwork will not only enhance Terminal 5 but also contribute to Chicago’s vibrant cultural landscape. Thank you for being part of the MFP family, and here’s to the artistry, precision, and dedication that define our journey.

“MFP’s involvement in this project is a testament to our unwavering commitment to creativity, craftsmanship, and innovation. We believe that this artwork will not only enhance Terminal 5 but also contribute to Chicago’s vibrant cultural landscape. Thank you for being part of the MFP family, and here’s to the artistry, precision, and dedication that define our journey.”

Mike McNeese – Operations Manager, Metal Fabrication Professionals